Traditionally known for their world-leading food and beverage process equipment, DC Norris are also experts in dog and cat wet pet food processing solutions.

The Company has worked hand in hand with customers to develop a variety of innovative cooking and cooling methods to give pet food manufacturers a choice depending on their desired product.

Jet Process

DCN recently launched the award-winning Jet Process System which is ideal for those manufacturers who require reduced processing times, large throughputs and high temperature sterilisation.

We look at some of the benefits of Jet Process:

High Speed & Large Throughputs

Jet Process allows the dog or cat food to reach temperatures of up to 148°C in seconds.

Powders such as gums, gels, vitamins and hydrocolloids are entrained, heated, mixed and hydrated in single figure minutes.

A recent installation required a footprint of only 120 sqm. and can produce 18,000Kgs of wet pet food per hour.

Small Footprint

With Jet Process pet food manufacturers can reduce the amount of processing vessels used. The system can cook, entrain (mix and hydrate hydrocolloids) and sterilise in a single pass removing the need for large retorts.

A traditional wet pet food system may have a large footprint and incorporate multiple jacketed or pressure vessels, emulsifiers, heat exchangers and retorts.

Low Water, Energy & Labour Costs

Jet Process removes the need for multiple vessels which have more processing stages using excess energy and increasing cost. Large volumes of water and caustic are also needed for the vessels to clean and remove burn-on.

Jet Process can be operated by just one person, reducing the amount of labour needed.

Sous Vide for Pet Food Processing

A recent trend in the pet food industry is for bespoke fresh prepared human-grade dog and cat food, and this is where our Sous Vide Systems may be more suitable.

This unique cooking process helps to maintain nutrients and maximise flavour for happy, healthy pets. Sous Vide dog food is vacuum sealed in air-tight plastic pouches that are cooked in water for a long period of time at a low temperature.

Sous Vide requires specialist packaging, vacuum sealing, a Cook Tank with temperature probes and controls, and appropriate chilling equipment.

Health Benefits

High temperature cooking methods often reduce the nutrients present in meats and vegetables. By lowering the cooking temperature, the sous vide cooking method ensures that foods retain as much of their nutritional value as possible.

High Yields

Sous Vide makes in virtually impossible to overcook or burn foods which dramatically increases yields. The cooking method also produces more flavourful foods without the use of added ingredients and fats as it locks in the natural juices.

Minimised Process & Labour Costs

Sous Vide cooking can be largely unsupervised, and foods cooked using this method can be cooked, chilled, stored and re-thermalized (in some applications) in the same packaging creating substantial cost savings.

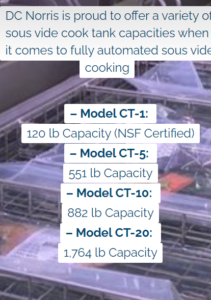

DC Norris offer a variety of fully automated Sous Vide Cook Tanks for dog and cat food – contact us for further information.

The post Discover DCN’s Wet Pet Food Processing Solutions appeared first on DC Norris.