The Benefits of Vacuum Cooling in Food Processing

As food manufacturers continue to look for ways to improve product quality, consistency and energy efficiency, vacuum cooling has become an increasingly valuable solution. This advanced cooling technology rapidly removes heat from cooked products using controlled pressure reduction, providing faster, more even cooling than traditional air or blast methods.

The Role of Vacuum Cooling in Food Processing

Effective temperature control is vital throughout food processing to maintain product integrity, ensure food safety and extend shelf life. Traditional cooling methods such as air or blast cooling can be time-consuming and may cool unevenly, particularly with dense or high-volume products.

Vacuum cooling in food processing offers a more controlled and efficient alternative. By creating a vacuum within a sealed chamber, the boiling point of water is reduced, causing a small amount of moisture to evaporate from the product’s surface. This phase change draws heat from the food, resulting in rapid, uniform cooling throughout.

In practical terms, modern systems can reduce product temperatures from around 90°C to 5°C in as little as 45 minutes, delivering a level of speed and consistency that is difficult to achieve with conventional cooling methods.

This makes vacuum cooling particularly suitable for ready meals, cooked meats, vegetables, sauces, soups, rice and baked goods – any application where consistent temperature control and product quality are essential.

What Makes Vacuum Cooling Machines Essential

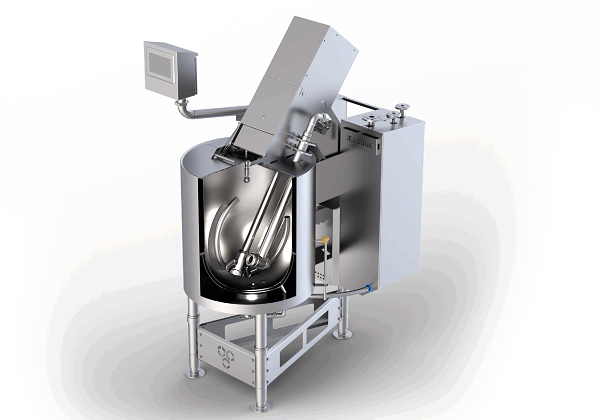

DC Norris’ vacuum cooling equipment is designed with hygiene, reliability and precision in mind. Each system provides a repeatable process that ensures accurate cooling profiles and consistent results from batch to batch.

The rapid, even cooling achieved within the chamber helps to stabilise product quality, retain structure, and minimise bacterial growth risk—key factors in maintaining high standards of food safety. Faster cooling also contributes to extended shelf life by limiting the time products spend in temperature ranges where micro-organisms can develop.

Vacuum cooling also prevents the formation of ice crystals and avoids overprocessing, helping to preserve texture, flavour and nutritional value. In addition, the fully automated control system allows operators to manage and record every cycle, supporting traceability and process validation.

Designed for high-capacity operations, these systems provide a fast and efficient solution for cooling large batches while maintaining consistent product quality.

The Environmental Benefits of Vacuum Cooling

Vacuum cooling technology also supports food manufacturers in achieving their environmental and sustainability objectives.

Reduced energy consumption:

The process is highly efficient, using natural evaporative cooling rather than extended refrigeration cycles or energy-intensive systems such as blast chilling or scrape surface cooling.

Optimised water usage:

Vacuum cooling removes a small amount of moisture from the product during the cooling process, which may be replenished depending on the application. Compared to some conventional cooling or processing methods, overall water use can be effectively managed and controlled within the process.

Reduced product loss:

Faster, more uniform cooling helps preserve product quality, extend shelf life and minimise waste.

Together, these advantages contribute to lower resource consumption and reduced operational costs, helping processors meet sustainability targets without compromising productivity.

How Vacuum Cooling Equipment Boosts Efficiency and Cuts Costs

For high-output food operations, the ability to cool products rapidly translates directly into process efficiency. Shorter cooling times free up production capacity, reduce bottlenecks and enable faster transitions between batches.

The speed of vacuum cooling supports faster production cycles, making it ideal for manufacturers looking to increase throughput without expanding their footprint.

In addition, the reduced reliance on traditional refrigeration systems can significantly lower capital and operational costs. The combination of energy savings, reduced handling time, improved yield, and extended shelf life delivers a strong and measurable return on investment.

In many facilities, vacuum cooling machines have become a key component of an integrated, efficient processing line.

In Summary

Vacuum cooling represents a modern, sustainable approach to temperature control in food production. Combining speed, precision and energy efficiency, it supports manufacturers in achieving consistent product quality, improved shelf life, and enhanced food safety while reducing overall costs and environmental impact.

At DC Norris, our vacuum cooling systems are engineered to meet the highest standards of hygiene, reliability and performance—helping customers worldwide to deliver safe, high-quality products with confidence.

When combined with our advanced cooking systems, vacuum cooling forms part of a complete DC Norris processing solution, designed to optimise every stage of production – from cooking through to filling and cooling.

We also offer complementary cooling technologies, including static batch coolers and tumble or belt chillers, ensuring the right solution for every application.

Discover more about our vacuum cooling equipment and integrated processing systems by contacting the DC Norris team today.

The post The Benefits of Vacuum Cooling in Food Processing appeared first on DC Norris.